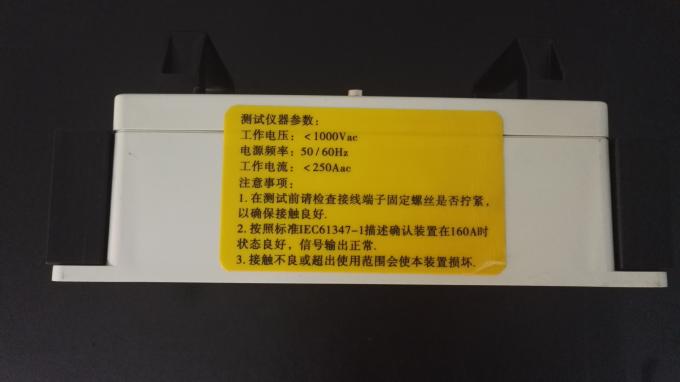

| Standard: | IEC 61347-1:2012, Clause 14.6 | Working Voltage: | <1000Vac |

|---|---|---|---|

| Working Frequency: | 50/60Hz | Working Current: | <500Aac<500Aac |

| Flow: | 160A +10% -0% Current Constantly | Function: | Current Test Device |

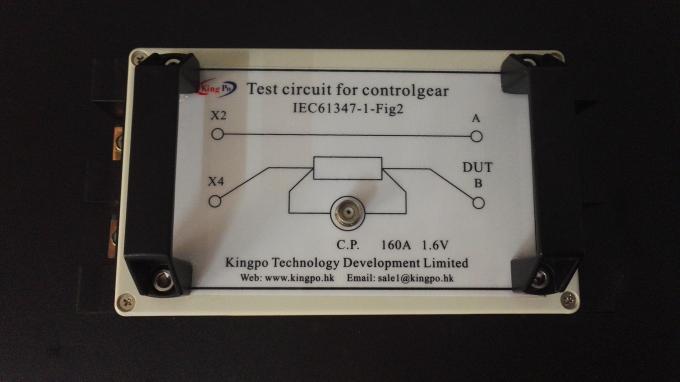

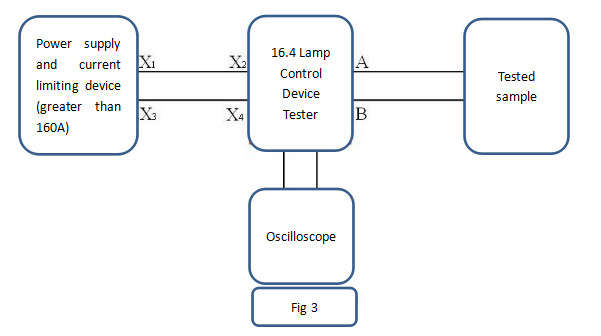

IEC 61347-1-2012-Figure 3 Test Circuit for Controlgear

Test principle

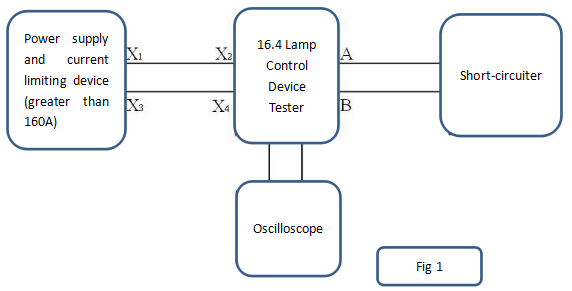

This tester is a current test device developed according to the IEC 61347-1:2012 standard, Article 14.6 requires current compliance; through the tester current measurement, it can determine whether the test conditions meet the “standard”.

Test Methods

1.1. According to the IEC 61347-1:2012 standard, clause 14.6 a requires that the circuit be connected, as shown in figure (1) :

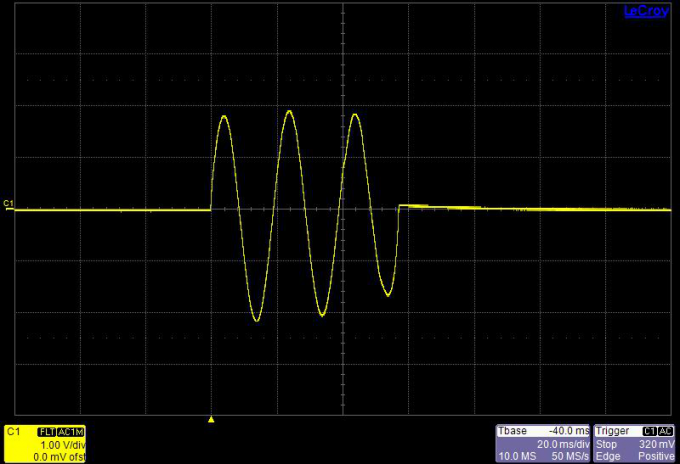

1.2 Adjust the oscilloscope input display ratio to X1, Y-axis adjustment to 1V/div, X-axis adjustment to 20mS/div, and the synchronization status is set to normal synchronization.

1.3 For example: connect the power supply, the oscilloscope waveform is the current of the test device, and the waveform is shown in figure 2.

Current reading method: peak voltage: 1.9V, peak current 190A (current to voltage ratio 100:1) RMS voltage: 1.34V, RMS current is 134A

According to the requirements of IEC 61347-1:2012, power supply and test equipment can be qualified to flow 160A +10% -0% current constantly.

2.1 According to IEC 61347-1:2012 standard, Clause 14.6-b connects the tested products, as shown in Figure below

3.1 According to IEC 61347-1:2012 standard, Clause 14.6-C, connect to the power supply for testing, oscilloscope setting method and current reading method is the same as 1.2,1.3.

Technical Parameters

1, working voltage: <1000Vac

2, working frequency: 50/60Hz

3, working current: <500Aac<500Aac

Note:

- Before the test, check whether the terminal fixing screws are tightened to ensure good contact.

- According to the standard “IEC61347-1:2012”, confirm that the state is good at 160A +10% -0%, and the signal output is normal.

- poor contact or beyond the scope of use can cause damage to the test device.